With the two pump set-up, a single pump can still run in case of a pump failure or pump service.

In larger pump stations it is safer to have 2 smaller pumps than one large pump. In this phase, a pump is selected to deliver the water required to the blocks and to flush the filter. The filters will act as the liver, to remove the finer debris that got past the pre-pump filtration, to ensure there are no blockages in the irrigation system’s outlets (sprinklers). a strainer and frog trap on the suction pipe. The lungs will be the pre-filtration i.e. The pump station can be seen as lungs, heart, and liver in the human body.

#Irrigation system designer full

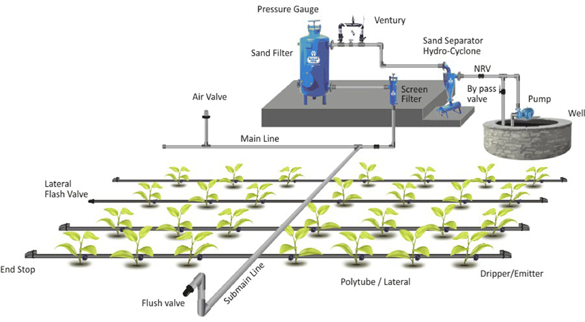

Outlets from LDPE pipes- are nylon insert or full flow fittings. The outlets from PVC pipes to laterals are grommets, saddles or solvent weld fittings. The sub-main could be one or a combination of PVC, LDPE or HDPE pipes. Grommet line) – The sub-main connects to the outlet of the valve leg. It is also common to see air valves fitted on these uprights as it is normally located at the highest points. The high-pressure pipes are used for uprights as they are more rigid to withstand the elements and vandalism which can be made from PVC pipes, galvanised steel pipes or HDPE pipes. High-pressure pipes (class 9 or 12) PVC pipe is used for theses T-offs. These pipes normally make an inverted U-shape to bring the control valve above the surface. Valve leg) – This is where the control valve is inserted to connect to the main line. The pipes in a block are subdivided into three categories. The pipe type to be used very important in this phase as each pipe type has different internal dimensions and friction coefficients. The design calculates the discharge of each sprinkler. On this block layout, a design is drawn up to manipulate pipe sizes for water uniformity of no less than 80%. Other reasons for irrigation block division is soil differences or cultivar differences. It also ensures better control over pressures through-out the block. The total area then gets sub divided into viable irrigation blocks, to reduce cost as larger blocks require larger pipes. This is done by sectioning unused areas like roads, netting-anchors or windbreaks.

This step sees that a block layout is done from the surveyed map to determine the cultivar area.

0 kommentar(er)

0 kommentar(er)